- Building envelope testing portable#

- Building envelope testing verification#

- Building envelope testing windows#

This is testing on fluid to the applied exterior wall weather resistance barrier.

Building envelope testing portable#

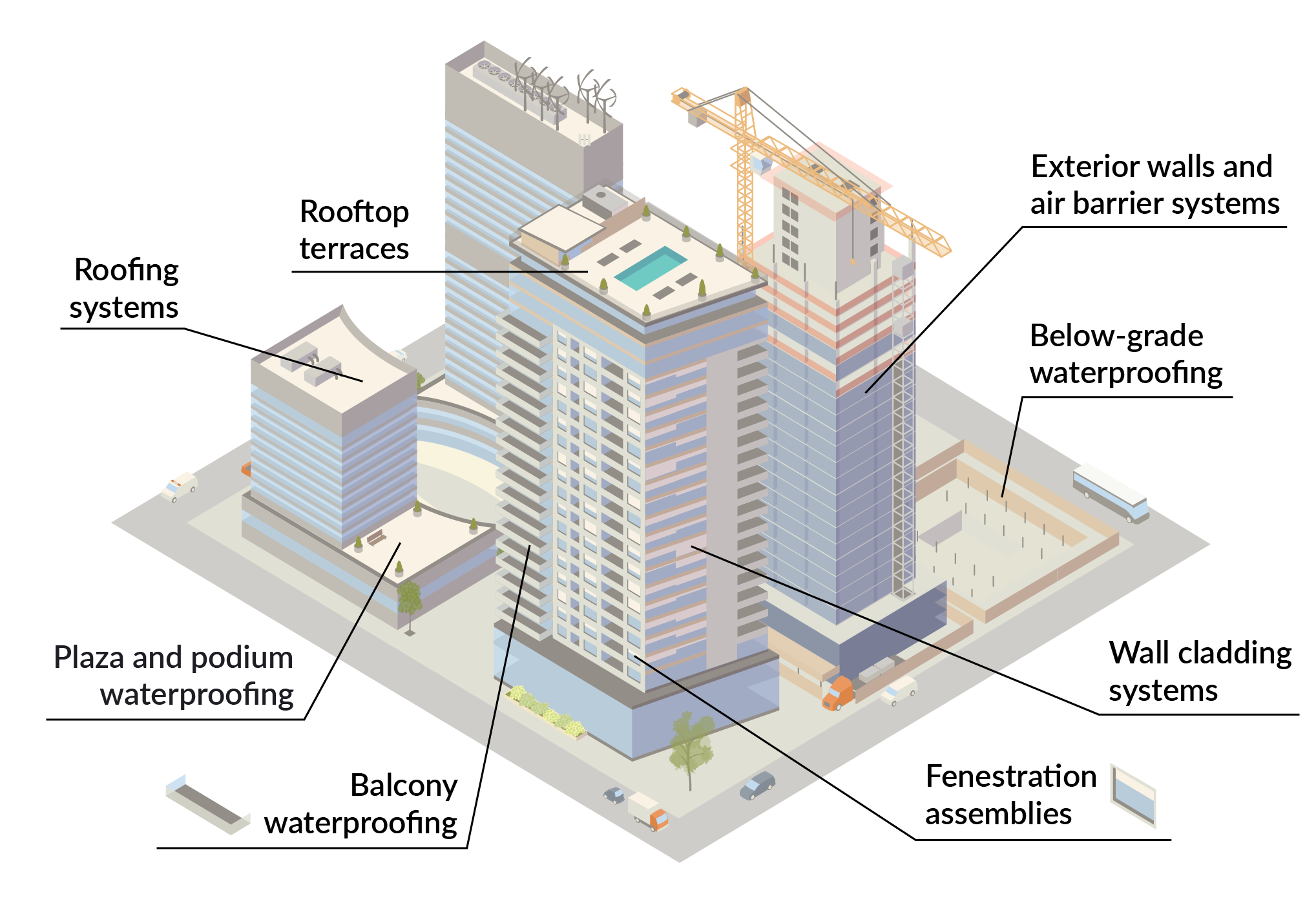

ASTM D4541: Method B Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers.ASTM D 7954/ D 7954 M: Moisture Surveying of Roofing and Waterproofing Systems Using Non-Destructive Electrical Impedance Scanners.ASTM D 5957: Standard Guide Flood Testing Horizontal Waterproofing Installations.ASTM E 2128: Standard Guide for Evaluating Water Leakage of Building Walls.ASTM C 1193: Standard Guide for Use of Joint Sealants, Appendix X1 – Method A, Field Applied Sealant Joint Hand Pull Tab.ASTM C 1521 – 09e1: Standard Practice for Evaluating Adhesion of Installed Weatherproofing Sealant Joints.ASTM Building Envelope Testing Services.Our experienced building envelope consultants finds the source of the problem, focusing on key culprits such as moisture intrusion, roofing failures, and exterior cladding material failures.ĪSTM / AAMA Window Field Testing Services Identifying and isolating problems is the first priority when issues arise.

Building envelope testing verification#

This includes verification that materials and flashing align with design documents.

We also perform roof-condition surveys, infrared thermal surveys and electronic moisture scans. Our non-intrusive electronic moisture scans detect moisture below the roof membrane, saving in costly repairs on interior damages and possible roof replacement. We perform proactive roof observations at the beginning, middle and final phase of your project.

Building envelope testing windows#

Those windows that are identified with high areas of air leakage are then tested with the water resistance testing. This testing can be used without disturbing the construction activity.

Our quality assurance tests examine the building envelope using an ultra-sonic technology to detect gaps, holes or deficiencies on the most common leak culprits, including glazing seals of windows, assembly of the window frame, flashing and perimeter sealant. Our testing services use a state-of-the art ultrasonic leak detection as a pre-test to identify high areas of air leakage. The frustration of a water leak is further magnified when the location of the leak is unidentifiable. Our additional roof testing services include a comprehensive observation of the condition of the roof, including the four focus areas covered in the building envelope survey. If required, we can provide destructive testing services (i.e., drilling holes into exterior surfaces like stucco) to measure moisture inside the wall cavity.

Our extensive building envelope surveys, review and document property conditions from the roof edge to the foundation. More cost and time efficient in window water leak detectionĭownload our slide deck for more information on ultrasonic testing Building Envelope Surveys.Testing can be conducted in sequence with the installation.Less setup required and less destructive than water testing.More windows/doors can be tested on site.When combined with spray testing and infrared scans, our testing techniques are among the most comprehensive in the industry. This innovative approach uses sound transmitters to detect gaps as small as 0.01 inch without disturbing construction activity. Our ultrasonic leak technology is the first of its kind.

0 kommentar(er)

0 kommentar(er)